SCHAAN, Liechtenstein: Ivoclar has introduced IPS e.max Ceram Art, a ready-to-use line of stain, glaze and structure pastes for the customisation of ceramic restorations. The materials are designed to integrate into a variety of fabrication approaches, including press and CAD/CAM workflows as well as both monolithic and layered restorations. As the latest addition to the IPS e.max ceramic portfolio, IPS e.max Ceram Art is intended to support the finalisation of ceramic restorations.

In addition to conventional stain materials, the line includes glaze pastes featuring the Magic Glaze effect. Their viscosity is designed for application without beading or running and for achieving a natural surface shine. The pastes are also well suited to the one-shot technique, in which staining and glazing are combined in a single firing cycle, saving time and simplifying workflows. The range further includes firing-stable, cadmium-free gingiva shades intended to support natural-looking gingival characterisation across diverse phenotypes.

IPS e.max Ceram Art for natural-looking detail

The ready-to-use stain, glaze and structure pastes have been developed to make individual characterisation more efficient and predictable. Central to the IPS e.max Ceram Art system is a newly formulated material consistency that offers both stability and flow properties suitable for detailed characterisation. Customisations and effects can be applied in a controlled manner and are designed to remain where placed, maintaining detail after firing.

Owing to its adapted consistency, IPS e.max Ceram Art is well suited to wet-on-wet staining. A key feature of the ready-to-use pastes is the self-glazing effect, which can eliminate the need for an additional glaze firing in suitable cases.

In lifelike reconstructions, the aesthetics of the gingival area is increasingly important. Colour, translucency and structure vary greatly among individuals and significantly influence the overall appearance of the restoration. The new IPS e.max Ceram Art gingiva materials are available in a wide range of shades to reproduce a broad spectrum of phenotypic variations. These materials are intended to support reconstructions in which gingival areas blend with the surrounding tissue and appear natural.

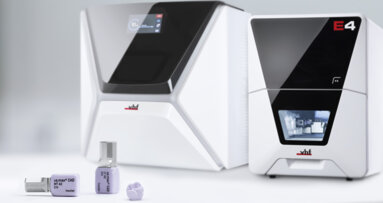

The new product line also supports detailed surface design. The form-stable structure pastes can be used to create targeted 3D effects, such as tooth or gingiva textures, without the need for an additional layering step. Together, these features are intended to support both creative design and consistent application. The materials are coordinated with Ivoclar’s ceramic framework materials such as the lithium disilicates IPS e.max Press and IPS e.max CAD, as well as the zirconia IPS e.max ZirCAD. They can also be used for the characterisation of Ivoclar’s metal–ceramic materials and other framework materials with a compatible coefficient of thermal expansion.

From concept to 20 years of IPS e.max

Since its introduction in 2005, IPS e.max has become a widely used ceramic system. Today, the portfolio includes lithium disilicate, zirconia and veneering ceramics, offering flexibility in indication, aesthetics and mechanical performance. IPS e.max Ceram Art is the newest addition, providing yet another option for ceramic design.

IPS e.max Ceram Art first edition kits

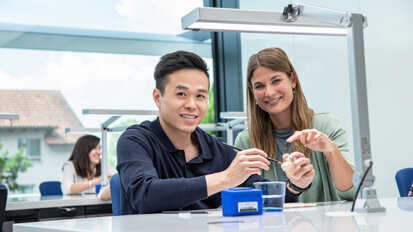

IPS e.max Ceram Art is now available as a limited first edition in participating markets, allowing dental technicians to work with the new product line before the official market launch. Only 750 kits are available, and each kit consists of the complete range of pastes to provide a solid introduction to working with IPS e.max Ceram Art. Training materials and application guidelines are supplied to support use in daily practice.

More information about IPS e.max Ceram Art, the product selection and its scope of applications is available here.

Tags:

SCHAAN, Liechtenstein: The Ivoclar Group, a leading manufacturer of integrated solutions for high-quality dental care, has published the fourth volume of ...

AMMERBUCH, Germany: The Ivoclar Group, a global provider of integrated solutions for high-quality dental care, and vhf camfacture, a leading manufacturer of...

LONDON, England: The Ivoclar Summer School, an international education initiative for dental students, was held in the UK for the first time this summer. ...

SCHAAN, Liechtenstein: The Ivoclar Group, a leading manufacturer of integrated solutions for high-quality dental applications, and MALO ...

In a rapidly evolving dental landscape shaped by digitalisation, artificial intelligence and rising patient expectations, Ivoclar continues to focus on ...

Dr. Maximilian Dobbertin M.Sc

Dr. med. dent. Simona-Georgiana Schick

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register