Dental LT Comfort Resin: Versatile and comfortable

Dental LT Comfort Resin is specifically designed to meet the diverse needs of patients and dental professionals. This new formula for the production of resilient occlusal splints creates a new spectrum of material classification that lies between traditional soft splints and traditional hard acrylic splints. Splints printed with Dental LT Comfort Resin become flexible in intra-oral conditions, providing wearing comfort to the patient and thus increasing the probability of compliance with treatment, but still have the properties to provide occlusal stability (Shore hardness D: 75). Moreover, bleaching trays can be printed with this material, providing dental professionals with a comprehensive solution for various dental applications with a single resin.

IBT Flex Resin: Enhanced performance and versatility

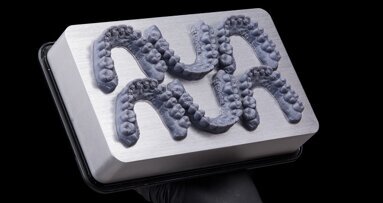

IBT Flex Resin represents a significant advancement in dental 3D printing, especially for the restorative field. This biocompatible material has been reformulated to meet the demanding requirements of indirect bonding trays. Now, dental professionals can also print direct composite restoration guides for provisional or permanent applications. The material’s superior strength, flexibility and accuracy, provided by the 50 μm layer height setting, enable dental professionals to achieve accurate results while reducing workflow complexity and turnaround times compared with traditional workflows.

Premium Teeth Resin: Multiple restorative indications

Premium Teeth Resin provides dental professionals with a strong, wear-resistant material with natural aesthetics for creating printed teeth for digital dentures, temporary full-arch implant-supported restorations (all-on-X), temporary single units (crowns, inlays, onlays and veneers) and up to seven-unit bridges. Compared with previous years and tooth-coloured resin generations, we are seeing an extension of clinical indications for both temporary and permanent use with new formulas. This provides a great deal of flexibility to dental professionals, as they can now resolve a wider range of clinical cases with a single resin.

Certified and open materials platforms

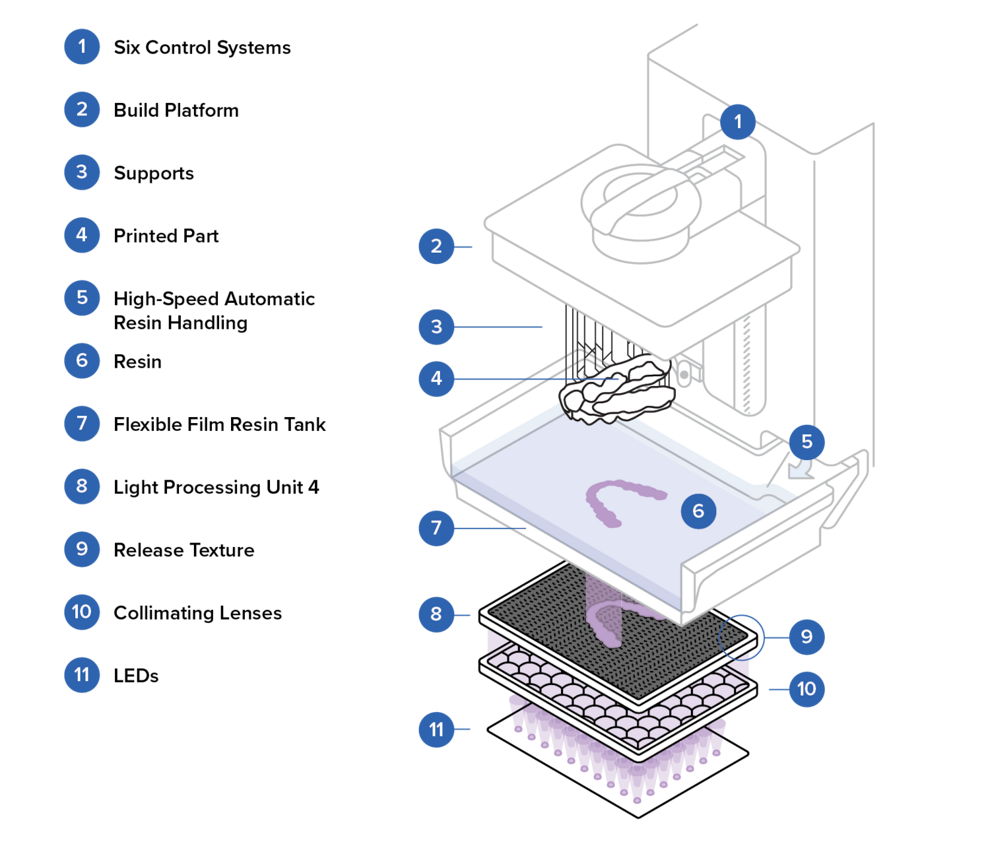

We will continue to see increased collaboration between resin manufacturers and 3D-printing companies to offer a specific selection of certified third-party resins for use with their 3D printers. For example, Formlabs runs a certified materials programme, collaborating with companies like BEGO to enable their restorative materials to work seamlessly with Formlabs’ hardware. Such collaborations involve thorough cross-testing, validation and the development of optimised settings by both companies. Additionally, software like Formlabs’ Open Material Mode will continue to expand, allowing dental professionals to use any 405 nm photopolymer resin with Form series printers. This empowers expert users and researchers to print with a wide range of market-available and custom resins. However, users must be aware of the requirements and responsibilities this entails, such as developing their own settings and conducting additional testing to ensure that the final product meets clinical standards.

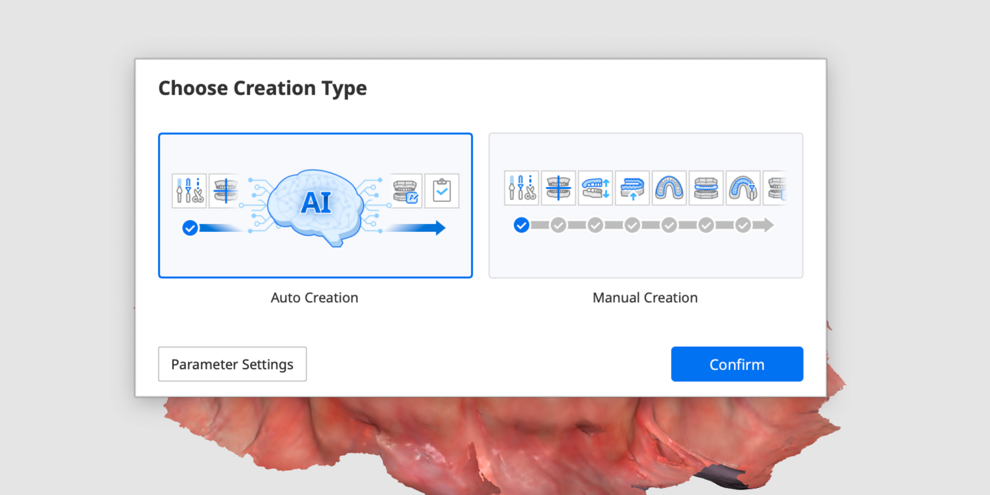

Driving innovation in dental care with digital tools that optimise workflows

In conclusion, the integration of AI, automation, hardware optimisation and material innovation continues to propel the evolution of dental 3D-printing workflows. These advancements not only optimise efficiency and precision but also expand the possibilities for dental professionals, ultimately leading to improved patient care and outcomes. By embracing emerging technologies and leveraging innovative solutions, the dental industry is poised to revolutionise patient care and usher in a new era of dental excellence.

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register