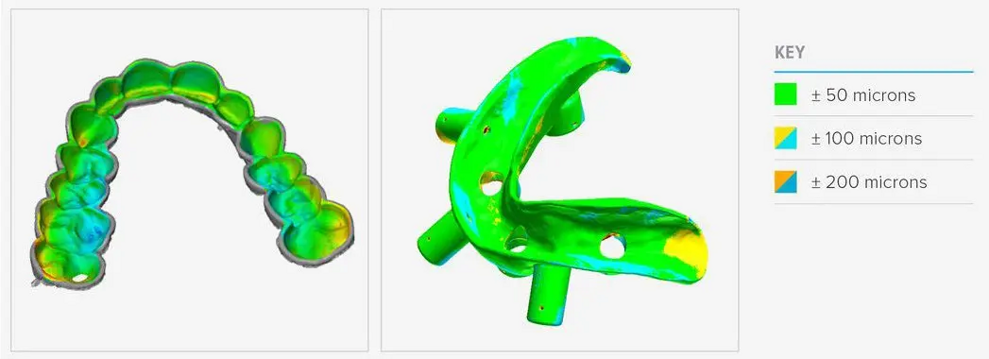

Some aspects are different. With the digital workflow, precision and accuracy can be quantitatively measured, such as via surface scanning and comparison with the digital impression (Fig. 1). This is fundamental for predicting how parts will adapt intra-orally and has the added benefit of peace of mind for both clinician and patient that the prostheses and appliances are suitably accurate for the patient’s condition.

Additionally, the timing of the delivery of digital products may have implications for the patient’s appointment schedule. For example, for a complete denture, the digital workflow requires half the number of appointments compared with traditional workflows. Moreover, in case of loss or fracture, a new denture can be easily refabricated using the digital files and only a seating appointment is required.

Comparing milling and 3D printing

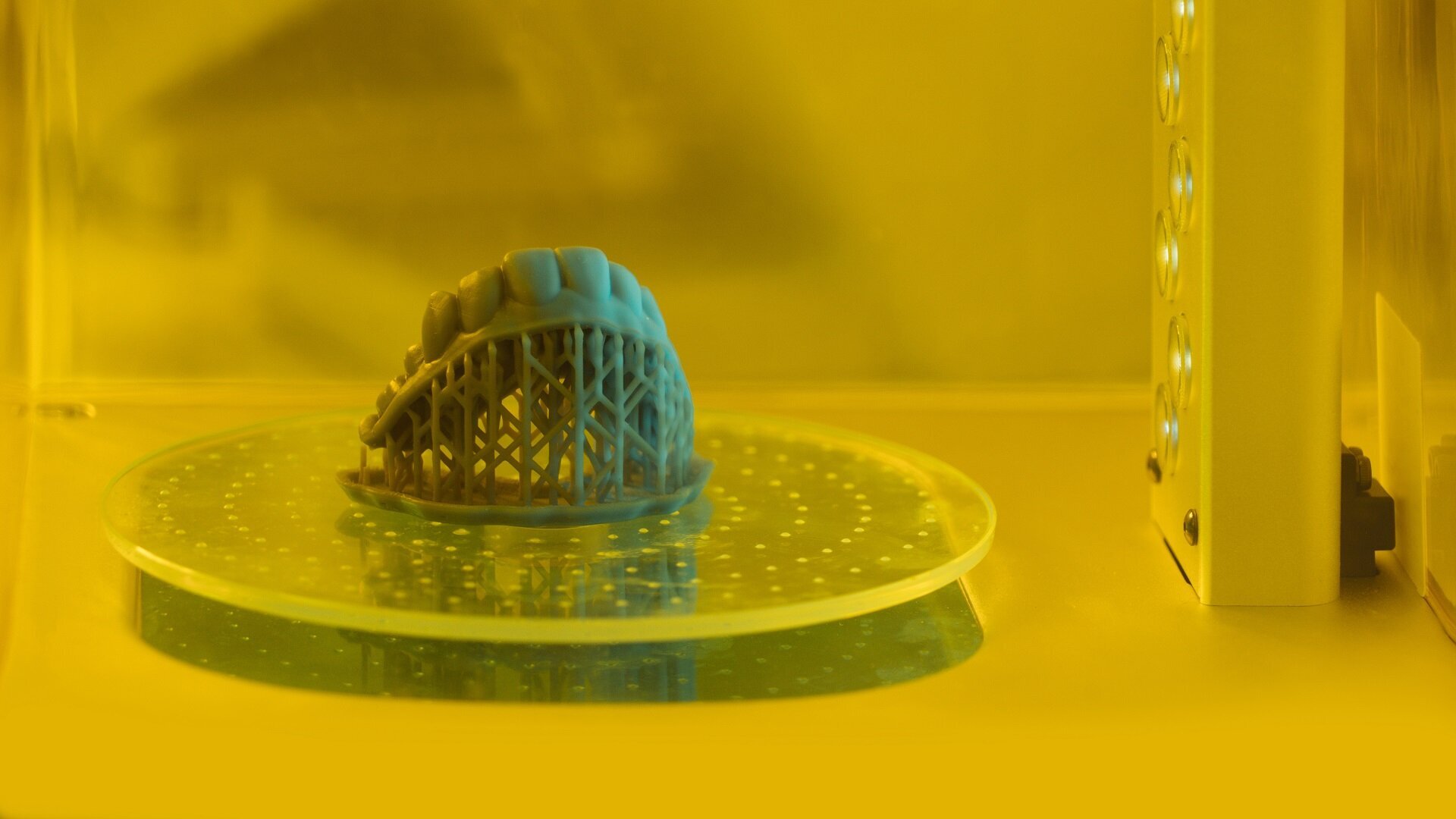

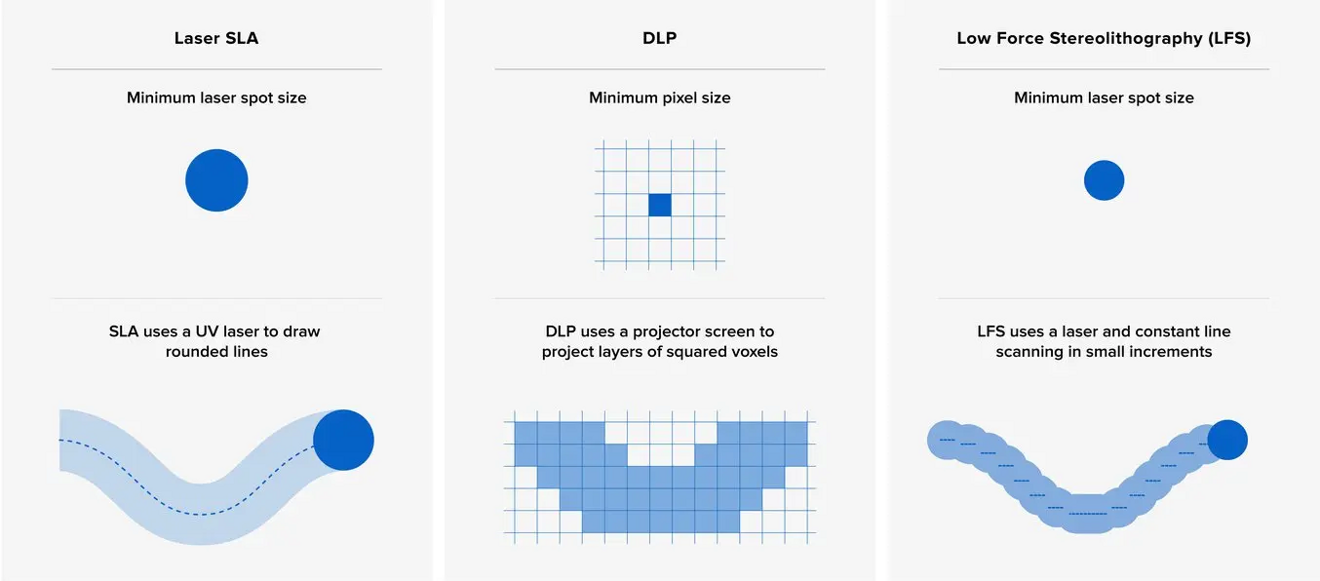

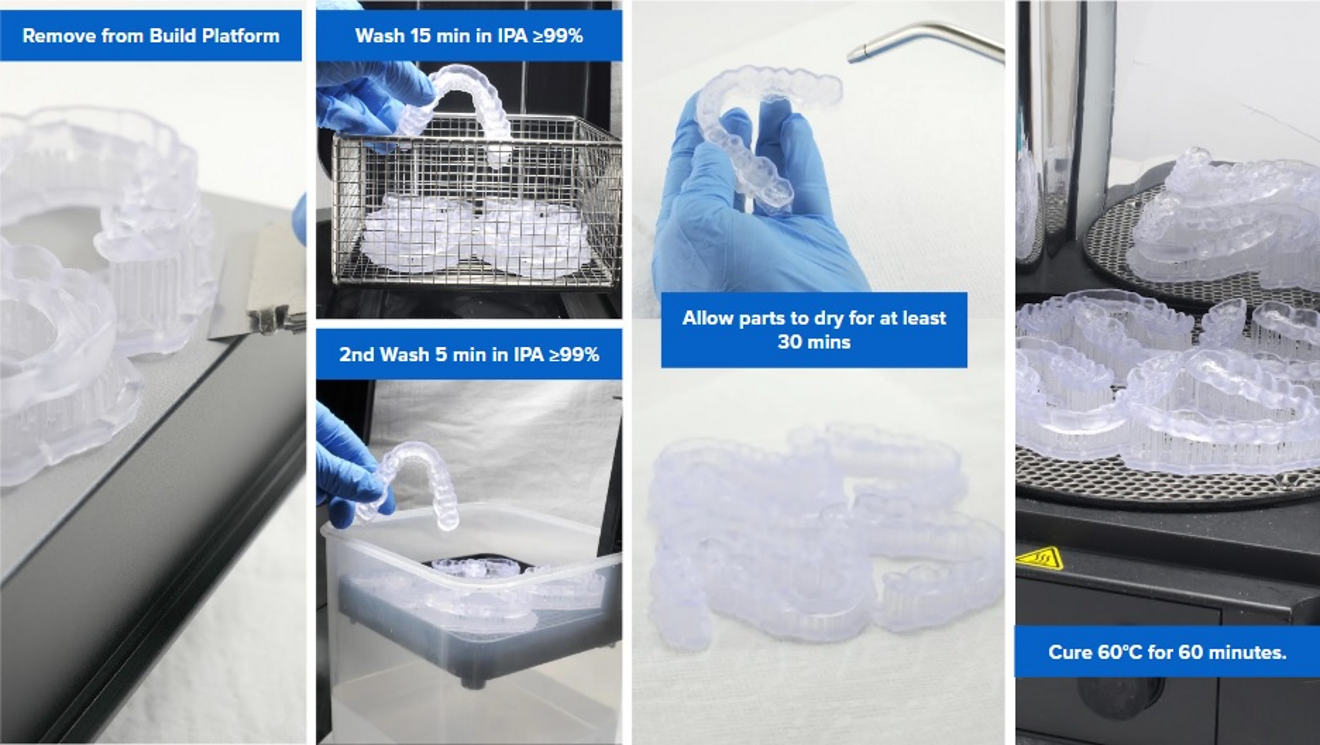

Milling has been used in the dental profession for longer than 3D printing. The most significant difference between the two technologies is how they are conducted. Milling, or subtractive manufacturing, begins with a solid block of material (such as PMMA or zirconia) and uses cutting tools to remove material until the final shape is achieved. In contrast, 3D printing, or additive manufacturing, uses various processes to build up the raw material into its final shape, one layer at a time. Dental 3D printers typically use a viscous liquid resin that reacts with light to become solid, using a laser or other light source to selectively expose the material to light and polymerise it in place.

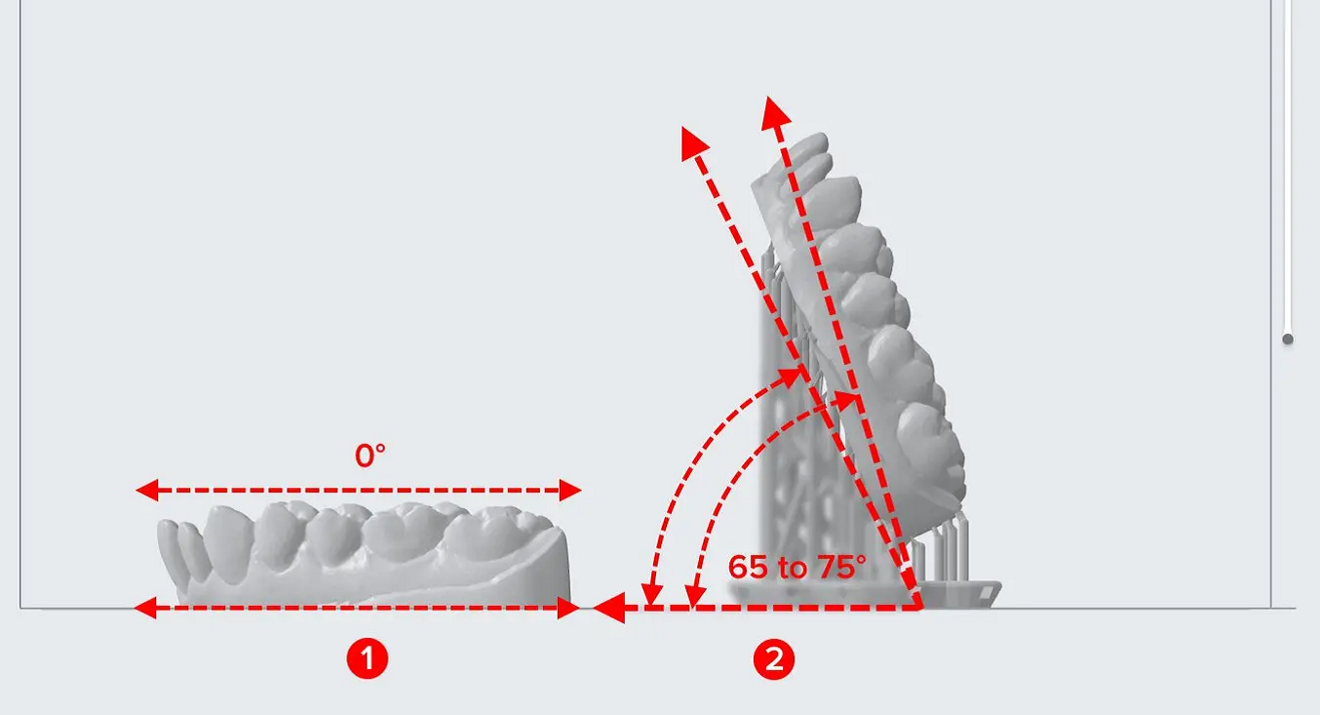

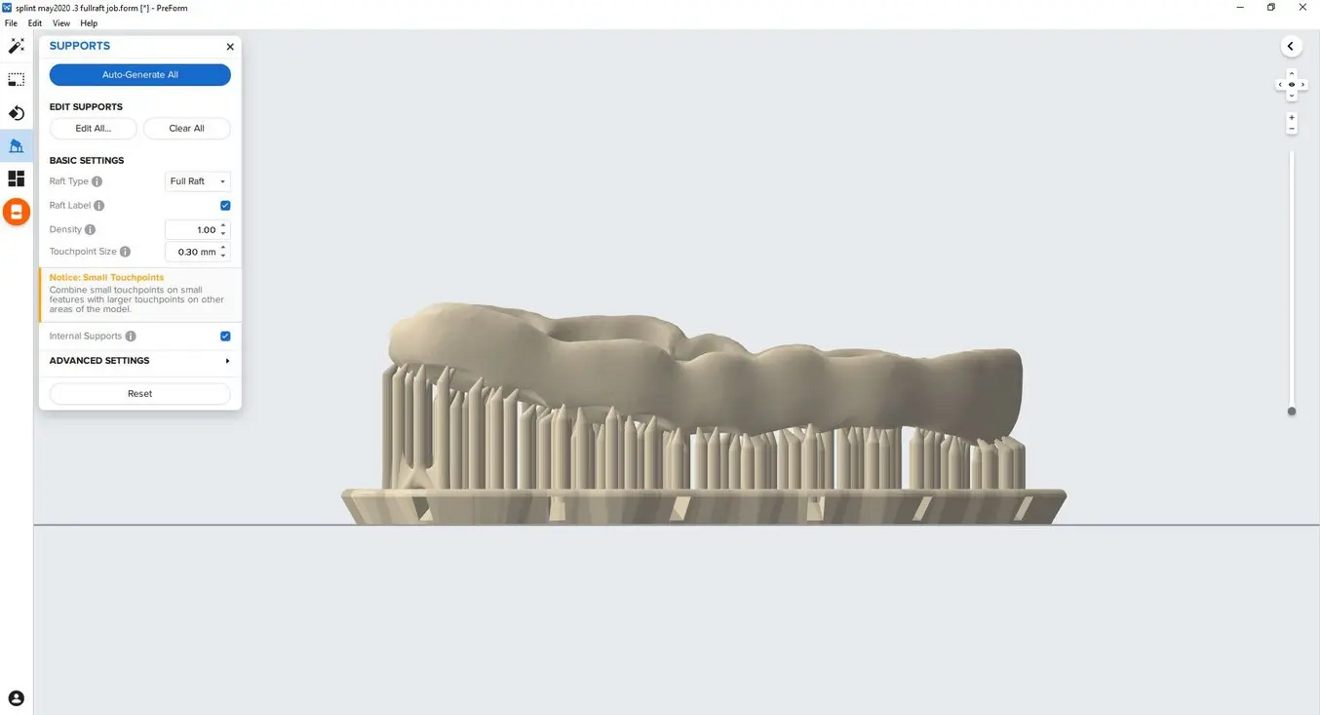

Given the difference in the nature of the manufacturing processes, the design parameters to bear in mind are different. In milling, we acknowledge limitations such as milling radius compensation during the design and preparation of our restoration or splint for its specific output. In 3D printing, there are fewer design limitations, but file preparation for manufacturing requires more attention, such as the orientation of the part relative to the printer (Fig. 2) and the use of supporting structures to hold the part securely during the printing process (Fig. 3).

The costs of operation and maintenance of each manufacturing option are relevant when analysing investment. In milling, it is important to acknowledge the total waste generated in production, as well as the long-term maintenance costs. In printing, the waste is reduced owing to the nature of the manufacturing process, but some equipment requires nearly as much maintenance as milling machines, and consumables like resin tanks can be expensive.

Lastly, the materials available and developed for each manufacturing system and clinical indication are important to analyse and understand, as well as the clinical scenarios for which dental professionals will opt for one technology or the other.

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register