VIENNA, Austria: The demand for aesthetic, natural-looking restorations is continually increasing. This trend favours ceramic implant solutions with high levels of biocompatibility, particularly zirconia, known for its excellent soft-tissue compatibility. The CERALOG Implant System is established and has been in clinical use for more than seven years. CAMLOG is showcasing its implant system at this year’s EAO congress from 11 to 13 October.

The implants offer a high level of predictability and provide aesthetically pleasing results, according to the company. The two-piece design of the system, which allows for screw-retained prostheses, provides many benefits.

Owing to the simplified prostheses, lean instrumentation and clearly structured surgical procedure, the CERALOG Implant System is easy to use. Options for the treatment workflow include flexible trans- or submucosal healing of the two-piece CERALOG Hexalobe Implant and transmucosal healing of the CERALOG Monobloc Implant.

The implants are made of yttria-stabilised tetragonal zirconia, which is a ceramic widely used in the dental industry. The ivory colour of the material, which is very close to that of a natural tooth, and the properties of zirconia lead to natural-looking results. Zirconia is chemically inert, making it especially suitable as an implant material. Owing to the manufacturing process of ceramic injection moulding, it offers an outstanding combination of excellent mechanical properties and high strength, according to the company.

The CERALOG Hexalobe offers the ideal implant–abutment connection. It was developed and optimised specifically for the zirconia implant. The force transmission is introduced optimally into the implant. Furthermore, the design offers rotational stability and precise manufacturing ensures a long-term stable outcome of the restoration.

The prostheses of the CERALOG Implant System consist of straight and angled abutments made of the polymer polyether ketone ketone (PEKK). The abutment is fixed to the implant via either a titanium or a gold screw. PEKK is easily processed with conventional milling equipment and belongs to the polyaryl ether ketone polymer family. These materials are required and used for extreme conditions, for example in automotive engineering, the aerospace industry and medical engineering. Because of their chemical structure, they offer tensile strength, rigidity and hydrolysis resistance. In addition to its long-standing use in orthopaedics, PEKK covers a broad spectrum of indications in dentistry, such as in restorations where stress shielding has to be reduced. The ductility of PEKK reduces the stress on the implant and simulates a tooth-like behaviour.

To learn more about CAMLOG’s products, EAO 2018 visitors are welcome to stop at Booth G12.

Tags:

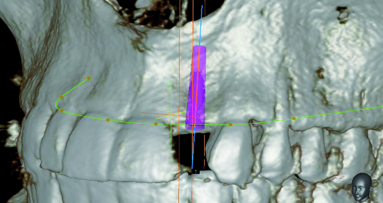

Maxillary lateral incisor agenesis (MLIA) is a congenital condition in which at least one of the maxillary lateral incisors is missing in the primary or ...

LISBON, Portugal: The INVERTA implant represents the latest breakthrough technology from Southern Implants and is designed for optimising aesthetics in ...

VIENNA, Austria: Swiss dental provider Cendres+Métaux is presenting its hybrid abutment range at the 2018 European Association for Osseointegration (EAO) ...

The absence of the maxillary lateral incisors creates a functional and esthetic problem that can be managed with different treatment modalities.

COLOGNE, Germany: Dentium is a leading manufacturer of dental implant systems and solutions, used by clinicians in more than 70 countries worldwide. As an ...

BASEL, Switzerland: Straumann, global leader in tooth replacement and orthodontic solutions, has entered a strategic partnership with Swiss-based ...

HELSINKI, Finland: The Nordic Institute of Dental Education (NIDE) is a Planmeca subsidiary specialising in high-quality continuing education (CE). As an ...

ESCHBORN, Germany: Osstem Implant provides a comprehensive range of products for guided bone regeneration (GBR), including materials for volume-preserving ...

COLOGNE, Germany: At the International Dental Show (IDS) 2025, the Ivoclar Group is celebrating 20 years of IPS e.max, its globally successful ceramic ...

Faced by a missing lateral incisor, practitioners often consider a wide range of issues and are also faced by numerous treatment options:

1. in a young ...

Live webinar

Tue. 24 February 2026

1:00 pm EST (New York)

Prof. Dr. Markus B. Hürzeler

Live webinar

Tue. 24 February 2026

3:00 pm EST (New York)

Prof. Dr. Marcel A. Wainwright DDS, PhD

Live webinar

Wed. 25 February 2026

11:00 am EST (New York)

Prof. Dr. Daniel Edelhoff

Live webinar

Wed. 25 February 2026

1:00 pm EST (New York)

Live webinar

Wed. 25 February 2026

8:00 pm EST (New York)

Live webinar

Tue. 3 March 2026

11:00 am EST (New York)

Dr. Omar Lugo Cirujano Maxilofacial

Live webinar

Tue. 3 March 2026

8:00 pm EST (New York)

Dr. Vasiliki Maseli DDS, MS, EdM

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register