Kuraray Noritake Dental is well known as a pioneer in multilayered zirconia technology and veneering porcelains. Are there any products particularly suitable or specifically developed for micro-layering?

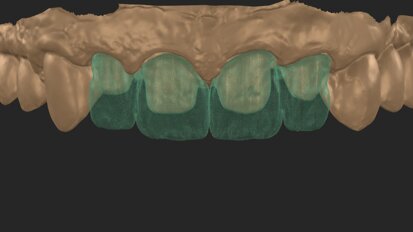

We offer a series of high-translucency, multilayered zirconia options perfectly suited for micro-layering on the one hand and an aligned portfolio of internal stains and porcelains specifically developed for micro-layering on the other. The zirconia portfolio includes three different blank types with a multilayered colour structure (KATANA Zirconia UTML, STML and HTML PLUS), one variant that features gradation in flexural strength, translucency and colour (KATANA Zirconia YML) and the timeless classic KATANA Zirconia HT for frameworks. While the first three offer a uniform strength and are chosen based on the indication, KATANA Zirconia YML with its multilayered strength is a universal material suitable for an extremely wide range of applications.

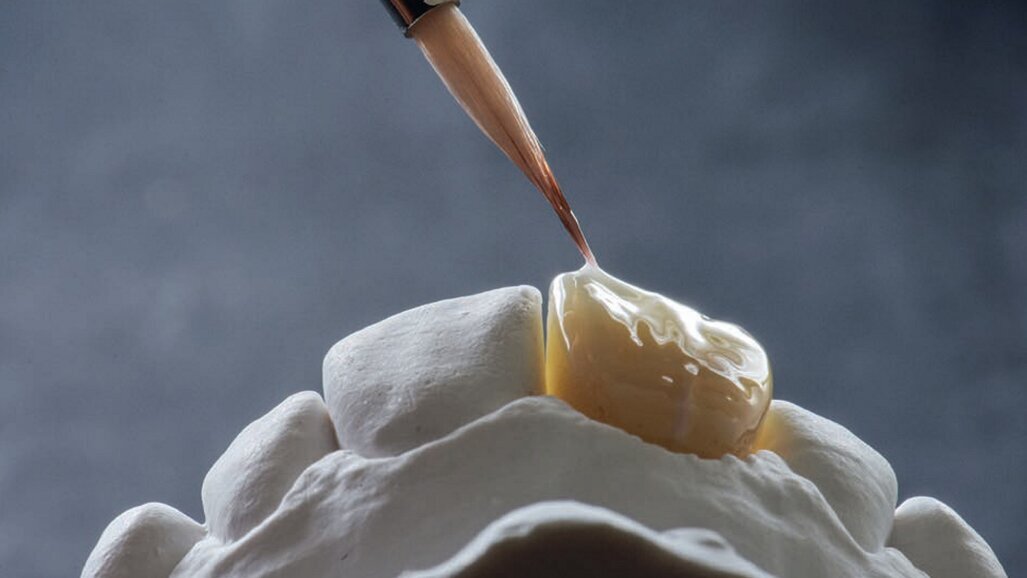

We have just introduced CERABIEN MiLai, a set of internal stains and porcelains specifically designed for the micro-layering technique. This addition to the CERABIEN family offers a perfect complement to the KATANA Zirconia multilayered series and, with it, a revolutionary workflow that significantly deviates from traditional methods, enabling us to deliver greater efficiency and cost-savings, as well as more flexibility. However, CERABIEN MiLai is compatible not only with KATANA Zirconia but also with aesthetic zirconia from other manufacturers and with reinforced silicate ceramics such as lithium disilicate with a coefficient of thermal expansion in the range of 9.5–11.0 × 10 –6 K–1 (50–500 °C).

Why should dental technicians start using the micro-layering technique and invest in a new set of porcelains for this purpose?

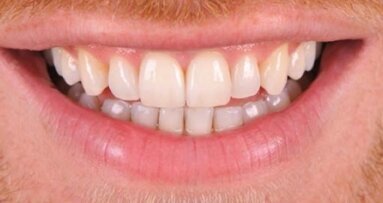

The reasons to start micro-layering are obvious: depending on the design, micro-layering can eliminate or minimise chipping risk. Moreover, the technique is highly efficient because the number of layers and bakes is drastically reduced. This results in a thinner restoration, facilitating minimally invasive preparation, and requires a less complex layering procedure that even beginners are able to learn and implement very quickly. The CERABIEN MiLai set of porcelains specifically developed for micro-layering can further support the feasibility of the technique and the quality of the outcomes achieved, even by beginners. Owing to the shortage of skilled workers in dental laboratories, this aspect is becoming increasingly important.

How does CERABIEN MiLai support users in achieving aesthetic, high-quality outcomes right from the start?

With traditional porcelain systems, it can be challenging to create all the desired individual shade effects in a layer of only 0.03–0.6 mm thick. For CERABIEN MiLai, this isn’t the case, because the system has been specifically designed for this purpose. The saturation and translucency of the porcelains are matched to the framework materials and adjusted to the volume of the porcelain layer. The compact line-up makes it quite easy to select and combine the right shades for satisfying results right from the start. More experienced users can mix the different components for additional effects—no limits are placed on their creativity.

Furthermore, the versatility of CERABIEN MiLai is a key feature that results in great outcomes. The system can be used on lithium disilicate and zirconia, a monolithic surface, a vestibular cutback or a full micro-cutback. Considering this broad application spectrum, dental technicians are likely to use CERABIEN MiLai daily, which will allow them to develop a true understanding of the components and to establish work routines very quickly, supporting predictable and controllable outcomes as a consequence. This is further supported by consistent handling and optical properties—all the result of a single core technology.

Could you please tell readers more about this technology?

The core technology used in CERABIEN MiLai is synthetic feldspathic ceramic technology. Originally developed for Noritake Super Porcelain EX-3 and adjusted to the specific needs of CERABIEN ZR initially and of CERABIEN MiLai more recently, this technology ensures consistent properties. This is because the formulation does not rely on naturally variable components and therefore requires no adjustments over time. However, I believe that the greatest benefit of using feldspathic porcelain lies in the elimination of shadow effects. Everyone familiar with layering natural feldspathic porcelains on ceramics will know about the typical greyish shadows that appear in restorations after several firing cycles. These originate from inhomogeneities in the material caused by micro-movements during firing. Showing no movements in this phase, synthetic felspathic porcelains from Kuraray Noritake Dental are the only porcelains that prevent this effect. Finally, the further developed version of the technology allowed us to realise a low firing temperature of just 740 °C while maintaining the desired coefficient of thermal expansion. This is essential for the material’s compatibility with lithium disilicate.

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register