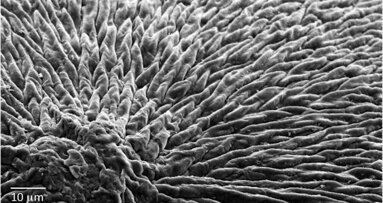

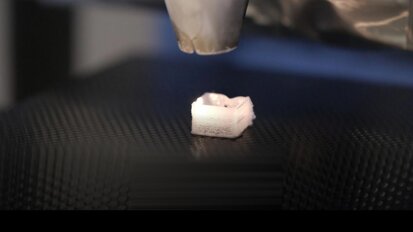

PORTLAND, Ore., U.S.: In a recent development that could have a huge impact on the dental industry, researchers from the Oregon Health and Science University School of Dentistry have developed a material that replicates human bone tissue. It can be produced in 72 days or less with an unprecedented level of precision, from its microscopic crystalline structure to its biological activity, and has been referred to as “bone in a dish”.

Speaking to Dental Tribune International regarding the process of developing the new material, lead researcher Dr. Luiz E. Bertassoni said that the journey had been a long one, from identifying the nanoscale characteristics of bone and other mineralized tissue to subsequently learning and optimizing a process to grow blood capillaries and neuronal networks in vitro. “After we had those pieces of the puzzle, which we sort of accumulated over the years, we began to concentrate on the development of a system that could calcify cell-loaded hydrogels to mimic the nanoscale structure and composition of bone.”

Testing a number of proteins and polymers that are known to promote nanoscale calcification of collagen, Bertassoni and his team then set out to optimize the conditions required to culture cells in the solutions, before fine-tuning the system that led to functional blood capillaries, nerve fibers and bone metabolism. “If our predictions are correct, this could mean that large bone defects that currently do not heal by themselves and require autologous bone transplantation may actually be regenerated better with these materials. We are currently testing that. In a way, it’s like we are able to make real human bone—with nearly all of its complexity—in the lab in a matter of 72 days or less, in a highly controllable method.”

The short space of time in which the material can be produced is another exciting element of the study. According to Bertassoni, because the researchers can start and stop the process as they please and can also add more or less calcium and phosphate, the environment is highly controlled, which therefore produces fast results.

However, the fast results are not impressive without material accuracy. Bertassoni explained that the trick of being able to produce bone down to the nanometer scale is to mimic nature to the closest degree possible. “We have known for a while that bone mineralization is orchestrated by proteins. Nature does this in a funny way, where it prevents mineral precipitation to actually form a mineral crystallite. So, we adopted a similar approach. We used a highly efficient precipitation inhibitor—which is counterintuitive—to actually form a mineral crystal and that allowed the ‘liquid’ mineral ions to infiltrate into the nanoporosity of collagen (the major protein in bone) like water seeps into the tiniest little holes. Once the infiltration has taken place, the proteins are removed and ions crystalize into the exact shape and form of mineral crystals in the native bone.”

The researchers are pushing for the material to be available in the next few years. “This is an area where regulatory hurdles are still very significant, and that may delay things a bit for clinical use. But the technology is being actively optimized for wider use,” said Bertassoni.

The study, titled “Rapid fabrication of vascularized and innervated cell-laden bone models with biomimetic intrafibrillar collagen mineralization,” was published on Aug. 6, 2019, in Nature Communications.

Tags:

LONDON, UK: Unlike many other tissues in the human body, dental enamel does not regenerate itself once it is damaged. In what could potentially be a ...

WÜRZBURG, Germany: Conventionally, the production of a dental crown requires several dentist appointments in order to complete the treatment. Researchers ...

LOS ANGELES, U.S.: Recent studies showing an increase in patients with periodontitis, as well as studies linking it with Alzheimer’s disease, have led to ...

LEEDS, UK: Xerostomia is a prevalent condition especially among older adults, cancer patients and people taking multiple medications. Researchers at the ...

SÃO PAULO, Brazil: In a discovery that may help the early identification of oral squamous cell carcinoma (OSCC), researchers in Brazil have found a ...

WASHINGTON, U.S.: Prevention is always the best place to start when talking about dental care; however, many patients would be thrilled to have access to an...

PERUGIA, Italy: In recent years, the landscape of dental prosthesis fabrication has seen a significant shift with the advent of additive manufacturing ...

MEDFORD, Mass., US: Stress can present as a wide range of physical, emotional and social symptoms, such as irritability, headache, anxiety and elevated ...

TORONTO, Canada: Researchers from the University of Toronto (U of T) have recently been awarded a grant to develop a new restorative material for treating ...

PORTLAND, Ore., U.S.: A recent study has found that a compound used to make car bumpers more robust and protect wood decks could make dental fillings last ...

Live webinar

Tue. 3 March 2026

11:00 am EST (New York)

Dr. Omar Lugo Cirujano Maxilofacial

Live webinar

Tue. 3 March 2026

8:00 pm EST (New York)

Dr. Vasiliki Maseli DDS, MS, EdM

Live webinar

Wed. 4 March 2026

12:00 pm EST (New York)

Munther Sulieman LDS RCS (Eng) BDS (Lond) MSc PhD

Live webinar

Wed. 4 March 2026

1:00 pm EST (New York)

Live webinar

Fri. 6 March 2026

3:00 am EST (New York)

Live webinar

Tue. 10 March 2026

4:00 am EST (New York)

Assoc. Prof. Aaron Davis, Prof. Sarah Baker

Live webinar

Tue. 10 March 2026

8:00 pm EST (New York)

Dr. Vasiliki Maseli DDS, MS, EdM

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

Interesting article