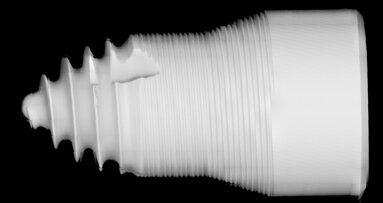

BERLIN, Germany: The CleanImplant Foundation, an established authority in evaluating the quality and cleanliness of implant surfaces, has awarded its Certified Production Quality seal of excellence to Komet Custom Made, a German supplier and original design manufacturer of ceramic implants.

According to Dr Dirk U. Duddeck, managing director and head of research at the CleanImplant Foundation, scanning electron microscope (SEM) analyses of more than 100 different commercially available implant systems found that more than half demonstrated significant impurities.

“These contaminants on new, sterile-packaged implants, which are entirely preventable on the manufacturer’s side, unfortunately have clinical consequences and harm both practitioners and patients,” Dr Duddeck stated. “It is our responsibility to inform dentists accordingly and provide a stage for quality manufacturers,” he continued.

Quality assured by rigorous testing

Based on the established CleanImplant consensus guideline on the cleanliness of dental implants, the Certified Production Quality seal is only awarded by the independent non-profit organisation after an extensive testing process conducted in an accredited testing laboratory. This certification is awarded to contract manufacturers such as Komet Custom Made that produce high-quality implants for various trade labels.

“The certification by the CleanImplant Foundation for ceramic implants confirms the process reliability of the quality assurance measures in place at the company, including validated final cleaning and subsequent packaging in the clean room, and represents a further milestone in ensuring the overall ceramic competence of Komet Custom Made,” noted Carsten Cieslik, general manager of Komet Custom Made.

As part of the family-run company Brasseler, Komet Custom Made offers a range of services, including implant design expertise based on many years of experience, the sophisticated packaging and manufacturing of ceramic implants, and the provision of other material and equipment, including abutments and implantology drills.

A beneficial mark for implant suppliers

Suppliers of implants produced by companies carrying the Certified Production Quality seal can benefit from this marker in multiple ways. The initiation of testing to obtain the coveted Trusted Quality Mark is facilitated by the CleanImplant Foundation. Conceptualised as an orientation tool for dental professionals, this mark may be awarded only after SEM analysis of five randomly selected samples of the same type and a final peer review of all results.

Tags:

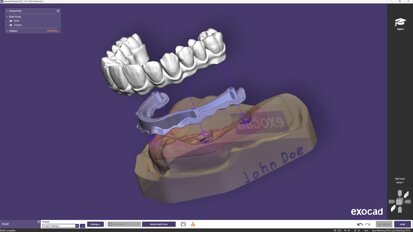

COLOGNE, Germany: This year at the International Dental Show (IDS), 3Shape is celebrating 25 years in CAD/CAM. However, it was first in 2005 that 3Shape ...

Centuries ago, dentistry identified mineral deposits, such as calculus, as the main cause of dental disease. Further research then recognised bacterial ...

The 30th edition of the UAE International Dental Conference and Arab Dental Exhibition (AEEDC Dubai) is presenting its most comprehensive scientific ...

BERLIN, Germany: On 6 January 2021, the CeramTec Group, a world innovation leader for advanced ceramics, was awarded the Certified Production Quality seal ...

Periapical implant lesions may be a cause of early failure of implants. The purpose of this article is to describe the surgical treatment of the periapical ...

LONDON, UK: Introduced in 2006, the whiteSKY system from bredent has proved its efficiency in clinical practice and scientific studies. At the congress of ...

In an interview with Dental Tribune International, Prof. Dr Katja Nelson talks about her findings on patients with oral cancer after rehabilitation with ...

The figures speak for themselves. Last year’s AEEDC Dubai attracted over 70,000 participants and featured more than 5,000 dental brands. The world’s ...

KREUZLINGEN, Switzerland: For the third time this year, the CleanImplant Foundation has awarded its Trusted Quality Mark for outstanding surface ...

VIENNA, Austria: Residues on sterile packaged implants, in particular, organic particles from the production or packaging process, are strongly suspected of...

Live webinar

Wed. 4 March 2026

12:00 pm EST (New York)

Munther Sulieman LDS RCS (Eng) BDS (Lond) MSc PhD

Live webinar

Wed. 4 March 2026

1:00 pm EST (New York)

Live webinar

Wed. 4 March 2026

8:30 pm EST (New York)

Lancette VanGuilder BS, RDH, PHEDH, CEAS, FADHA

Live webinar

Fri. 6 March 2026

3:00 am EST (New York)

Live webinar

Mon. 9 March 2026

12:30 pm EST (New York)

Live webinar

Mon. 9 March 2026

3:00 pm EST (New York)

Live webinar

Tue. 10 March 2026

4:00 am EST (New York)

Assoc. Prof. Aaron Davis, Prof. Sarah Baker

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register