INDIANAPOLIS, US: Where time can realistically and safely be saved in dental and restorative treatments, so can both money and patient chair time. A new case series has documented the testing and use of 3D-printed shell complete dentures as a diagnostic tool in implant planning and provisional restoration fabrication to expedite full-arch restoration. The research highlights the potential of this approach to simplify and streamline the process and to save clinical and laboratory time, offering enhanced aesthetic outcomes and functional results.

With technological advancements in implant design, imaging and manufacturing, there is a shift towards more efficient planning and execution of implant-supported restorations. Digital technologies such as CAD/CAM have introduced new possibilities for creating precise dental appliances, including surgical guides and prostheses. These tools allow dental clinicians to overcome clinical challenges such as difficulty assessing the occlusal plane and complex surgical interventions, making digital workflows suitable for full-arch restoration with implants.

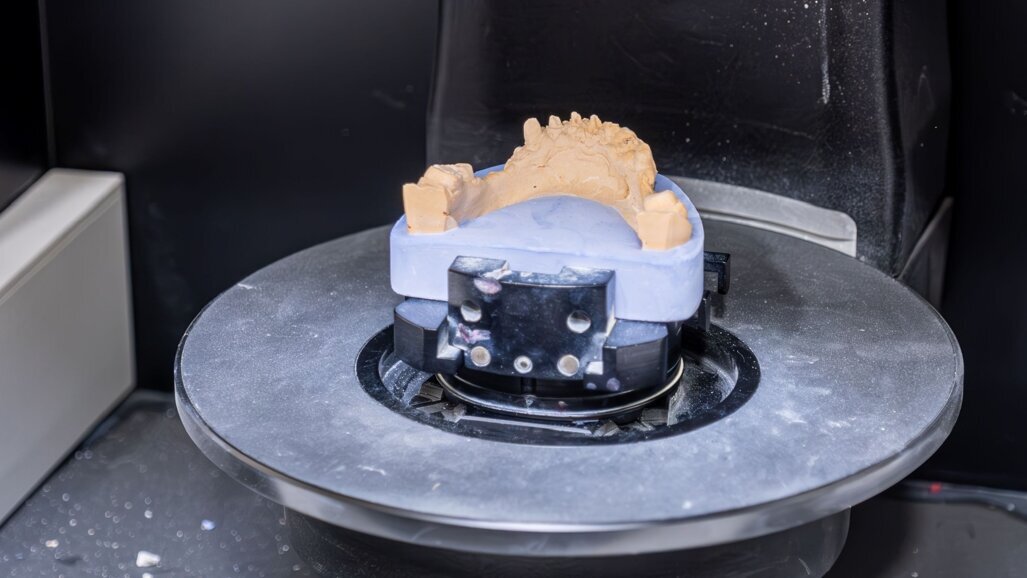

3D-printed shell complete dentures

Conventional methods involve creating radiographic templates from duplicate dentures or desired tooth set-ups to ensure ideal occlusion and aesthetic outcomes, whereas 3D-printed shell complete dentures are generated from the scans of the patient’s existing prostheses. They allow clinicians to assess critical aesthetic and functional parameters, such as facial support, lip position, vertical dimension of occlusion and occlusal plane orientation, before proceeding to implant placement. These dentures serve as a diagnostic aid, enabling clinicians to visualise, validate and modify the prosthodontic parameters without altering the patient’s existing prostheses. This approach is beneficial for identifying aesthetic and functional deficiencies and planning necessary modifications to create ideal final restorations.

These shell dentures guide the planning of implant location and the design of different types of provisional prostheses. As diagnostic devices, they support transfer of the intra-oral relationships to a semi-adjustable articulator and determination of what intra-oral adjustment is required before provisional prosthesis delivery.

By using existing prostheses as a template, 3D printing simplifies the creation of provisional restorations, saving time and resources. This efficiency is particularly valuable in cosmetic dentistry, where patient satisfaction and reduced treatment time are paramount.

The presented cases

The study presents a case series involving three patients who underwent full-arch restoration using the 3D-printed shell denture protocol. Each case illustrates the practical application and advantages of this technique.

The first patient presented with a maxillary complete denture, compromised mandibular teeth, a decreased vertical dimension of occlusion, an irregular occlusal plane and an unstable occlusion. Treatment involved provisional maxillary and mandibular prostheses, followed by a final maxillary complete denture and a mandibular implant-supported complete denture. The use of 3D-printed shell dentures allowed for accurate assessment and enhancement of aesthetic parameters.

The second patient presented with a severely resorbed maxillary arch, a partially edentulous mandible, a decreased vertical dimension of occlusion and an irregular occlusal plane. The treatment involved placement and immediate loading of six implants with a provisional complete denture, followed by a final maxillary complete denture and implant-supported restoration of the edentulous site #46. The 3D-printed shell complete dentures facilitated accurate implant placement and improved aesthetics.

The final patient presented with a severely resorbed maxillary arch, overerupted anterior mandibular teeth, and maxillary and mandibular removable prostheses showing excessive wear, irregular occlusion, significant discoloration and multiple repairs, indicating anterior hyperfunction syndrome. Treatment involved four zygomatic implants for the maxillary arch, restored with a provisional maxillary complete denture, and a new mandibular removable partial denture supported on two implants. The 3D-printed shell complete denture approach allowed for effective management of the complex anatomical changes and ensured satisfactory aesthetics and function.

Key components for success

The researchers emphasised the importance of thorough data collection and extra-oral and intra-oral assessment in implant planning from the beginning for full-arch restoration. By providing a tangible representation of the projected treatment, the 3D-printed shell dentures supported communication between the prosthodontist, oral surgeon and patient and encouraged patient treatment acceptance.

The process reduces the need for extensive occlusal adjustments and expedites the creation of provisional restorations, offering a significant time-saving advantage over traditional methods. Additionally, the ability to customise prosthetic appliances based on the patient’s existing dentures ensures that aesthetic and functional parameters are tailored to individual needs. The accuracy and precision of 3D-printed shell complete dentures lead to better implant positioning, improved aesthetic results and enhanced patient satisfaction, aligning with the goals of cosmetic dentistry and restorative practices.

The study, titled “3D-printed shell complete dentures as a diagnostic aid for implant planning and fabricating interim restorations for complete arch rehabilitations: A case series”, was published online on 22 July 2024 in the Journal of Prosthodontics, ahead of inclusion in an issue.

Topics:

Tags:

ISTANBUL, Turkey: Being able to accurately replicate intra-oral conditions is vital for successful restorative treatments. Although digital workflows have ...

Implant-supported restorations are becoming increasingly popular in contemporary dentistry, and the study of the osseointegration process has led to the ...

Digital workflows are constantly being improved with innovations in technique, software and materials and tailored to dental diseases and patient cases. ...

The use of 3D printers is rapidly gaining interest across the world. 3D printing is threatening to replace traditional subtractive CAD/CAM methods in ...

Live webinar

Wed. 25 February 2026

8:00 pm EST (New York)

Live webinar

Tue. 3 March 2026

11:00 am EST (New York)

Dr. Omar Lugo Cirujano Maxilofacial

Live webinar

Tue. 3 March 2026

8:00 pm EST (New York)

Dr. Vasiliki Maseli DDS, MS, EdM

Live webinar

Wed. 4 March 2026

12:00 pm EST (New York)

Munther Sulieman LDS RCS (Eng) BDS (Lond) MSc PhD

Live webinar

Wed. 4 March 2026

1:00 pm EST (New York)

Live webinar

Fri. 6 March 2026

3:00 am EST (New York)

Live webinar

Tue. 10 March 2026

4:00 am EST (New York)

Assoc. Prof. Aaron Davis, Prof. Sarah Baker

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register